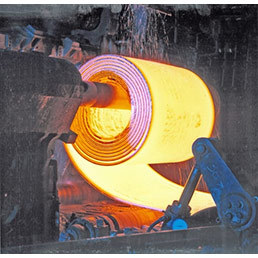

Narrow Strip Mill

80000000 INR/Unit

Product Details:

- Type Narrow Strip Mill

- Material Cast Iron

- Computerized Yes

- Automatic Grade Semi-Automatic

- Control System Frequency Speed Control

- Voltage 220-440 Volt (v)

- Warranty Yes

- Click to View more

X

Narrow Strip Mill Price And Quantity

- 1 Unit

- 80000000 INR/Unit

- 80000000.00 - 40000000.00 INR/Unit

Narrow Strip Mill Product Specifications

- Frequency Speed Control

- Cast Iron

- 220-440 Volt (v)

- Yes

- Yes

- Semi-Automatic

- Narrow Strip Mill

Narrow Strip Mill Trade Information

- 1 Unit Per Month

- 1 Week

- All India

Product Description

We, being a market-trustworthy manufacturer and supplier of Narrow Strip Rolling Mill that is proficient in constantly shaping cast- metallic strand into strips, have been successfully catering to Narrow Strip Mill requirement and demand of clients of India as well as African & South East Asian countries since 1974. Narrow strip mill, designed by us, assures desired thickness & edge of strips through using small and enlarged diameter rolls, is a standout in both local and international markets. The coil weight is to be amplified in order to meet the requirement of the pipe mill. Narrow strip mill should be designed in a configuration that assures uniform tension distribution across the strip in order to dimensionally homogenous strip products.

UGI Engineering provides all inclusive solution of narrow strip mill equipment, components, utility, drives, electrics and automation systems to suffice demand of the optimal performance, premium product quality and tremendous operational flexibility.

Cooling and Finishing Equipment :

Narrow strips coiled are edge with control to keep the edges in time. Vibratory slat conveyor is with controlled speed to feed the strip coiler

Coil Binding Machine :

Coil binding machine is automatic to strip the coil and put tags

Coil carrying Conveyors :

Coil carry conveyors are designed to prevent scratches on strip surface with optimum space utilization

Specifications:

- Thickness : 0.8mm to 8.0mm

- Width : upto 500mm

- Coil Weight : 1.50 MT

- Mill Size : 10,000 TPA to 200,000 TPA

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hot Rolling Mill' category

We mainly deal in export markets as Bangladesh, Nepal, Bhutan, UAE, Nigeria, Kenya and Gulf Countries.

|

UGI ENGINEERING WORKS PVT. LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free